- This topic is empty.

-

AuthorPosts

-

20/10/2025 at 16:19 #9770

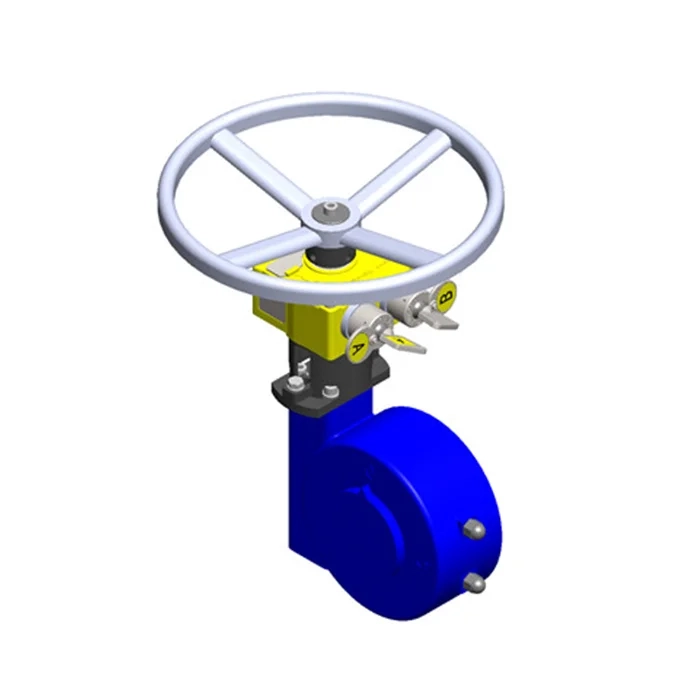

In modern industrial production, valve interlock systems are widely used in industries such as petrochemicals, energy, power, metallurgy, and environmental protection. They are not only a crucial component for ensuring equipment safety, but also a key tool for achieving automated control and industrial safety management. However, many companies often overlook pre-installation preparation and precautions when installing valve interlock systems, resulting in poor installation results and even safety hazards. This article systematically outlines key considerations companies must address before installing a valve interlock system, helping them complete system installation and commissioning efficiently and in a standardized manner.

1. Clarifying Installation Objectives and System Functional Requirements

Before installing a valve interlock system, companies must first clarify the system's functional requirements and installation objectives. The requirements for valve interlock systems vary significantly across different industrial scenarios. For example, the petrochemical industry has strict interlocking requirements for high-pressure and high-temperature pipelines, while water treatment plants prioritize automated control and remote monitoring. Key functional requirements include:

Safety interlock functionality: The system must prevent misoperation during operation to avoid liquid leakage, equipment damage, or personal injury.

Automated control requirements: Based on the company's production processes, determine whether the valve interlock system needs to be integrated with a DCS, PLC, or SCADA system for remote operation and automated management. Alarm and Monitoring Functions: The system should include fault alarms, status monitoring, and data logging, allowing managers to monitor the network's operating status in real time.

Clearly defining goals and requirements not only helps select the appropriate valve interlock system model but also provides a basis for subsequent installation planning, avoiding duplication of work or missing functionality.

2. Selecting the Appropriate Valve Interlock System Model

The valve interlock system model directly impacts system performance and safety. Companies should consider the following when selecting a model:

Suitability: Select a valve interlock system based on the pipeline's pressure, temperature, media characteristics, and environmental conditions. For example, high-temperature steam pipelines require high-temperature-resistant materials, while corrosive liquid pipelines require corrosion-resistant materials.

Interlocking Method: Select a method based on the control strategy. Different methods vary in interlocking accuracy, ease of operation, and maintenance costs.

Interface Compatibility: The system should be compatible with existing valves and control equipment to avoid subsequent modifications due to interface mismatches.

Brand and After-Sales Service: Select a supplier with industry experience and excellent after-sales service to ensure long-term stable system operation and technical support.

Selecting the appropriate system model is essential for smooth installation and subsequent stable operation, and is also a key step for companies to mitigate safety risks.

3. Pre-Installation Site Survey and Preparation

Before installing a valve interlock system, companies must conduct a comprehensive site survey to ensure that environmental conditions meet installation requirements. Key considerations include:

Pipe and Valve Inspection: Verify that the piping layout is reasonable, the number, specifications, and installation locations of valves meet design requirements, and that there are no leaks or damage.

Control Interface Inspection: Verify that the control cabinet, sensors, cables, and interfaces meet system requirements to ensure smooth subsequent wiring.

Space and Support Structure: Ensure that the installation location for the valve interlock system has sufficient space and a stable support structure for easy operation and maintenance.

Environmental Conditions: Pay attention to environmental conditions such as temperature, humidity, corrosion resistance, dust protection, and explosion resistance, ensuring that the system materials and protection level are suitable for site conditions.

A site survey not only identifies potential issues but also allows for pre-planning the installation process, reducing the risk of rework during installation.

4. Developing an Installation Plan and Construction Schedule

Installing a valve interlock system is not simply assembling equipment; it is a comprehensive project involving mechanical, electrical, and control systems. Therefore, companies need to develop a detailed installation plan and construction schedule, including:

Construction Sequence Planning: Clarify the installation sequence for valves, interlocks, electrical wiring, sensors, and control systems to ensure smooth transitions between each step.

Safety Measures: Protective devices and operating procedures must be implemented during installation to prevent high-pressure pipeline leaks, mechanical injuries, or electrical accidents.

Schedule and Personnel Arrangement: Rationally schedule the installation schedule to ensure coordination among various specialized construction personnel and avoid delays due to process conflicts.

Commissioning Plan: Plan the commissioning process in advance, including interlock operation testing, alarm function verification, and system linkage debugging, to ensure immediate operation after installation.

A sound installation plan is a prerequisite for the safe and efficient installation of the valve interlock system and a crucial guarantee for its subsequent stable operation.

5. Preparation of Installation Materials and Tools

Before installing the valve interlock system, companies must prepare sufficient installation materials and specialized tools to ensure smooth construction. Key areas include:

Installation Materials: This includes valve interlocks, cables, sensors, brackets, fasteners, protective covers, etc., and must comply with design specifications and operating requirements. Construction tools: such as wrenches, screwdrivers, levels, power tools, and welding equipment, to ensure installation accuracy and efficiency.

Testing instruments: Pressure gauges, voltmeters, and signal testers, used for commissioning and acceptance, facilitate system inspections after installation.

Adequate preparation of materials and tools can avoid construction interruptions due to material shortages or equipment mismatches, thereby improving installation efficiency.

6. Personnel Training and Operating Standards

The valve interlock system involves mechanical interlocks, electrical interlocks, and automated controls. Improper operation can lead to safety accidents. Therefore, companies should provide comprehensive personnel training before installation:

Operational Training: Construction personnel should be familiar with the valve interlock system structure, operating principles, and installation procedures, and strictly adhere to operating procedures.

Safety Education: Strengthen training on safe operation of high-pressure pipelines, electrical systems, and mechanical equipment to prevent accidents during construction.

Emergency Plan Training: Train personnel to familiarize themselves with emergency shutdown, pressure relief, and troubleshooting procedures, enhancing on-site emergency response capabilities.

Proper training and standardized operation are crucial for the safe installation and subsequent stable operation of the valve interlock system.

7. Pre-Installation Risk Assessment

Before installing a valve interlock system, companies should conduct a comprehensive risk assessment to identify potential safety hazards and technical difficulties, including:

Construction risks: such as working at height, mechanical injuries, and electrical shock.

Process risks: such as pipeline leakage, interlock operation errors, and system compatibility issues.

Environmental risks: such as the impact of temperature, humidity, corrosion, and dust on system materials and performance.

Through this risk assessment, companies can proactively implement protective measures and emergency plans to mitigate safety risks during installation.

Through scientific and standardized installation and management, valve interlock systems can not only effectively prevent misoperation and accidents but also improve overall production management efficiency. Companies must carefully adhere to all precautions before system installation to fully realize the value of valve interlock systems and achieve safe, reliable, and efficient industrial production.

As a professional valve interlock system supplier, Nudango leverages its extensive industry experience and technical expertise to provide companies with one-stop solutions from design and selection to installation and commissioning, providing a solid guarantee for production safety and management efficiency.

http://www.nudango.com

nudango -

AuthorPosts

- You must be logged in to reply to this topic.