- This topic is empty.

-

AuthorPosts

-

26/02/2025 at 18:06 #8008

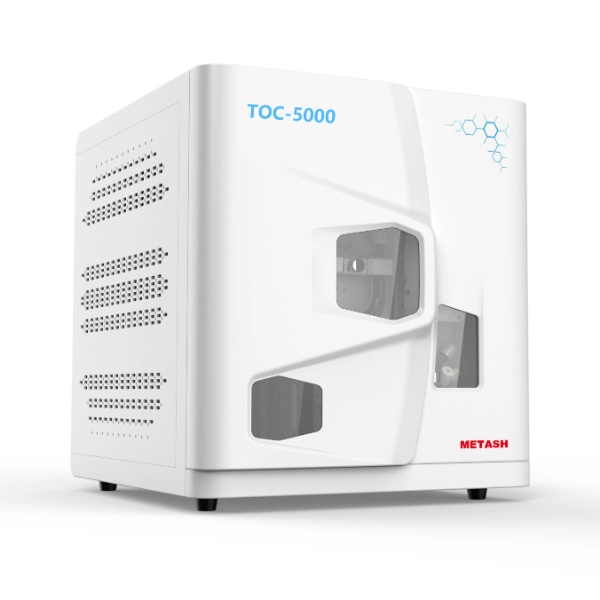

In various industries, from water treatment to pharmaceuticals, monitoring organic carbon content in water and wastewater is critical for quality control and environmental compliance. One of the most efficient methods for measuring total organic carbon (TOC) is through high temperature catalytic combustion. This technique is widely employed in TOC analyzers due to its accuracy, efficiency, and reliability in detecting organic contaminants. In this blog post, Metash will share the principles of high temperature catalytic combustion, its advantages, and its applications in TOC Total Organic Carbon Analyzer.

Understanding TOC and Its Significance

Total organic carbon (TOC) is a key parameter that represents the amount of organic carbon present in a water sample. It includes both dissolved and particulate organic matter and serves as an important indicator of water quality. Monitoring TOC levels is essential in various industries, including wastewater treatment, pharmaceutical production, food and beverage processing, and semiconductor manufacturing. High TOC levels can indicate contamination, process inefficiencies, or environmental pollution, making accurate TOC measurement a priority.

Principles of High Temperature Catalytic Combustion

High temperature catalytic combustion is a widely used method for TOC analysis due to its effectiveness in completely oxidizing organic carbon to carbon dioxide (CO2). The fundamental principle behind this technique involves three key steps:

1. Sample Injection: The water sample containing organic carbon is introduced into the combustion chamber.

2. Oxidation at High Temperatures: The sample is subjected to extremely high temperatures, typically ranging from 680°C to 1,200°C, in the presence of a catalytic material. The catalyst, usually platinum or another noble metal, enhances the oxidation process, ensuring complete conversion of all organic carbon into CO2.

3. Detection and Quantification: The CO2 generated from combustion is carried by a gas stream to a non-dispersive infrared (NDIR) detector, which measures the concentration of CO2. The TOC content is then calculated based on the detected CO2 levels.

Advantages of High Temperature Catalytic Combustion in TOC Analyzer

The high temperature catalytic combustion method offers several advantages over other TOC measurement techniques, such as wet chemical oxidation and UV-persulfate oxidation. These benefits include:

1. Complete Oxidation: The high temperatures and catalytic enhancement ensure that all organic carbon is fully oxidized to CO2, leading to accurate and reliable TOC measurements.

2. Wide Applicability: This method is suitable for a broad range of samples, including those with high levels of particulates, complex organic matrices, and volatile organic compounds (VOCs).

3. Fast and Efficient: High temperature catalytic combustion provides rapid results, making it ideal for real-time monitoring and process control.

4. Minimal Chemical Reagents: Unlike wet chemical oxidation, which requires strong acids and oxidizing agents, catalytic combustion relies primarily on heat and a catalyst, reducing reagent costs and waste.

5. Low Maintenance and Operational Costs: TOC analyzers using this method typically have fewer moving parts and require less frequent maintenance compared to other techniques.

Applications of High Temperature Catalytic Combustion in TOC Analyzer

1. Water and Wastewater Treatment

In municipal and industrial wastewater treatment plants, TOC analyzers help monitor organic contamination levels, ensuring compliance with environmental regulations and optimizing treatment processes.

2. Pharmaceutical and Biotech Industries

Pharmaceutical manufacturers use TOC analysis to ensure the purity of water used in drug formulation and manufacturing. The high sensitivity of catalytic combustion TOC analyzers allows for the detection of trace organic contaminants in purified water and water for injection (WFI).

3. Food and Beverage Industry

In beverage production, TOC monitoring is crucial for assessing water quality and maintaining product consistency. High temperature catalytic combustion ensures accurate detection of organic residues that may affect taste, color, or safety.

4. Semiconductor Manufacturing

Ultra-pure water (UPW) is essential in semiconductor fabrication. TOC analysis using high temperature catalytic combustion helps maintain the stringent water purity standards required for microchip production.

5. Environmental Monitoring

TOC analyzers are deployed in environmental research and regulatory compliance testing to assess organic pollution levels in surface water, groundwater, and industrial effluents.

Choosing the Right TOC Analyzer for sale

When selecting a TOC analyzer based on high temperature catalytic combustion, consider factors such as:

– Temperature Range: Ensure the analyzer operates at sufficiently high temperatures (typically above 680°C) to guarantee complete oxidation.

– Catalyst Type: A high-quality catalyst enhances oxidation efficiency and extends the analyzer's lifespan.

– Detection Sensitivity: Choose an analyzer with a sensitive CO2 detector to measure TOC accurately across a wide concentration range.

– Automation and Integration: Modern TOC analyzers offer automated calibration, self-cleaning features, and seamless integration with data management systems.

– Maintenance Requirements: Look for analyzers with minimal maintenance needs to reduce downtime and operational costs.

Conclusion

High temperature catalytic combustion remains one of the most effective and widely adopted methods for TOC analysis. Its ability to provide complete oxidation, accurate measurements, and broad applicability makes it a preferred choice in industries requiring stringent water quality monitoring. As technology continues to evolve, advancements in TOC analyzers will further improve efficiency, accuracy, and ease of use, ensuring reliable organic carbon analysis across diverse applications!

http://www.metashcorp.com

Metash -

AuthorPosts

- You must be logged in to reply to this topic.