- This topic is empty.

-

AuthorPosts

-

18/06/2025 at 16:50 #8824

In modern logistics, building partitions, and advertising decoration fields, lightweight and high strength have become core demands. PP hollow sheet reshapes industry standards with exceptional compressive strength, ultra-low thermal conductivity, 100% recyclable eco-features, and honeycomb structure weight reduction design! The unique air interlayer achieves "gram-level load-bearing", increasing strength-to-weight ratio by 180%, while integrating moisture-proof, sound insulation, and thermal insulation – a green pioneer replacing wood and metal sheets.

JWELL Production line introduction

Extruder

JWS120\JWS150 type extruder or add JWS65\JWS90 type for co-extruder.

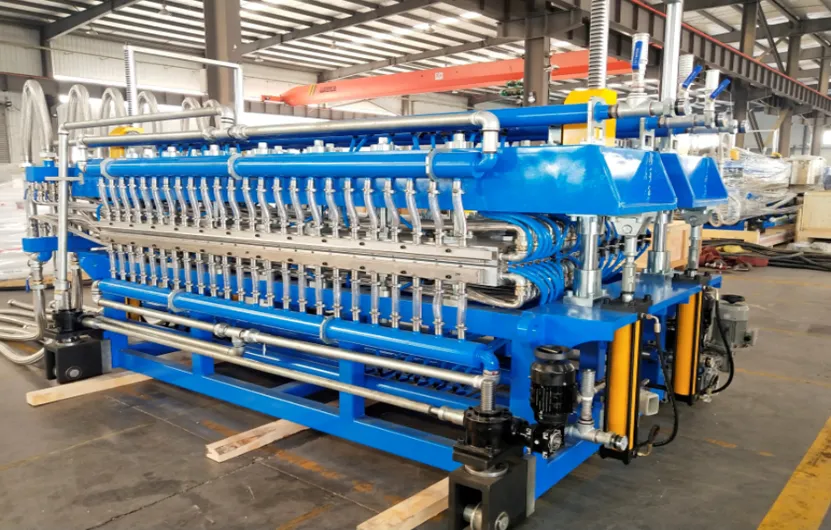

PP Hollow Sheet Special molds

It can be used as a flange to realize a set of molds to produce a variety of width products; The setting table needs to be adjusted and sealed.

An air knife is installed before entering the setting table to assist cooling.

Setting table

The PP setting table vacuums the surface of the product, the thickness of the setting plate is usually 80mm, the internal water is cooled, the water temperature is within 20°C, the hydraulic control lifting, and the thickness of the product is controlled by the thickness of the cushion block.

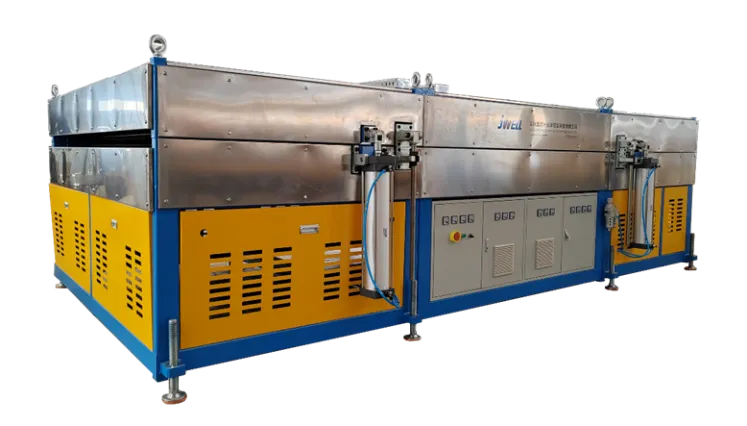

Oven

The freshly cooled products are baked at low temperature, so that the stress inside the products is released, and the warping and other phenomena are avoided after the products are completely cooled. The temperature can be adjusted in different areas, and the process of the product can be adjusted according to the actual situation.

Corona device

Since PP hollow lattice board is usually used in the packaging industry, the surface needs to be printed with all kinds of advertisements and slogans, and the paint, ink and plastic surface are not incompatible, so it is necessary to use a corona device to break through the microscopic holes on the surface of the product through discharge, so that the paint and ink are attached to it.

Bellows

The PP hollow lattice plate needs to be cooled sufficiently, and the device is assembled after the oven to cool it.

Shearing machine

PP grating board has a softer texture and usually uses a shearing machine, which is more efficient. When the line speed of the production line is fast and the length of the product is short, the cutting may be untimely when the cross-cutting machine is used.

Product Structure Types

Type

Applicable scenarios

Single-layer

Medium-wall hollow lightweight box lining with equal wall thickness

Reinforcement ribs

Logistics pallets with vertical stiffeners, building partitions

Composite flame retardant

(FRPP flame retardant layer) Protective cover for electrical equipment

Key Technical Parameters

Project

Parameter range

Extruder

JWS120\JWS150+\JWS65\JWS90

The width of the article

600-2700 mm

Lattice height

2-16mm

Line speed

3-15 m/min

Line speed

200-650 kg/h

Energy consumption

≤0.28 kWh/kg (Industry 0.35+)

Performance Benchmark

Characteristic

PP hollow lattice board

PP hollow lattice board (skin)

Solid PP board

Corrugated cardboard

Plywood (birch/poplar)

Density (g/cm³)

0.035-0.12

0.035 – 0.12

0.9-1.1

0.18-0.3

0.55-0.8

Flexural Strength (MPa)

45665

15-22

25-58

4-6.5

15-60

Thermal conductivity (W/m·K)

0.041

0.041

0.22

0.05

0.13

Water resistance

★★★★★☆

★★★★★d

★★★★★

★☆☆☆☆

★★★★★

Cycle life

50+ times

50+ times

50+ times

One time

10+ times

Jwell Guarantee · Lightweight Manufacturing Engine

As a global leader in polymer extrusion equipment, Jwell Machinery guarantees product production with high-quality equipment.

1. Efficient and intelligent: The PLC automatic control system realizes the automatic operation of the whole process, monitors and adjusts the parameters in real time, and increases the production efficiency by 30%.

2. Precise and stable: high-precision molds and intelligent control systems ensure that the thickness tolerance of the lattice plate is small, the plate surface is smooth, the structure is symmetrical, and a number of performance exceeds the industry standard.

3. Flexible customization: support to adjust the specifications, colors and functional characteristics of the plate according to the needs, quickly switch the production of different products, and adapt to the needs of multiple markets.

4. Green energy saving: energy-saving devices and servo motors reduce energy consumption by more than 25%, and the on line recycling of leftovers makes the utilization rate of raw materials reach 98%, practicing low-carbon production.

5. Intelligent O&M: Remote monitoring and diagnosis are realized through the Internet of Things, and problems are detected in advance by intelligent early warning, reducing equipment maintenance and labor management costs.

Complies with ISO 18616 international standard for logistics packaging. UL 94 V-0 flammability rating customization.

Note: The range of parameters can be expanded according to customer needs, and the flame retardant/antistatic and other functional layers can be customized.

Open your era of lightweight intelligent manufacturing!

http://www.jwellplas.com

Jwell machinery -

AuthorPosts

- You must be logged in to reply to this topic.